For Indian MSMEs and industrial enterprises, the transition from NC (Numerical Control) to CNC (Computer Numerical Control) machinery represents a massive leap in long-term profitability based on precision and scalability.

For businesses such as fabrication units or tool shops, the choice between NC and CNC is not just technical but a matter of strategic advantage. Let’s understand how CNC machines are transforming the manufacturing game, compare them with traditional NC systems, and explore machine loans and equipment financing to make them more accessible than ever.

Key Takeaways

- CNC machines are digitally driven, offering higher precision and consistency than NC machines.

- They allow for automation and repeatability and reduce human error. This makes them ideal for both large-scale and batch production.

- For MSMEs in India, machinery loans are a smart way to finance CNC upgrades without straining working capital.

- Choosing CNC over NC improves operational efficiency and increases the potential for growth, exports, and market competitiveness.

A Brief History of CNC Machines

NC (Numerical Control) machines were first introduced in the 1940s and 50s, driven by the aerospace industry’s need for accurate, repeatable components. These machines relied on punched tape or analogue input and had very limited flexibility.

CNC (Computer Numerical Control) machines arrived in the 1970s, powered by digital computing. With software-based programming and automation, CNC machines dramatically expanded what’s possible in precision manufacturing. Today, CNC has become the global standard, and for good reason.

What Are CNC Machines?

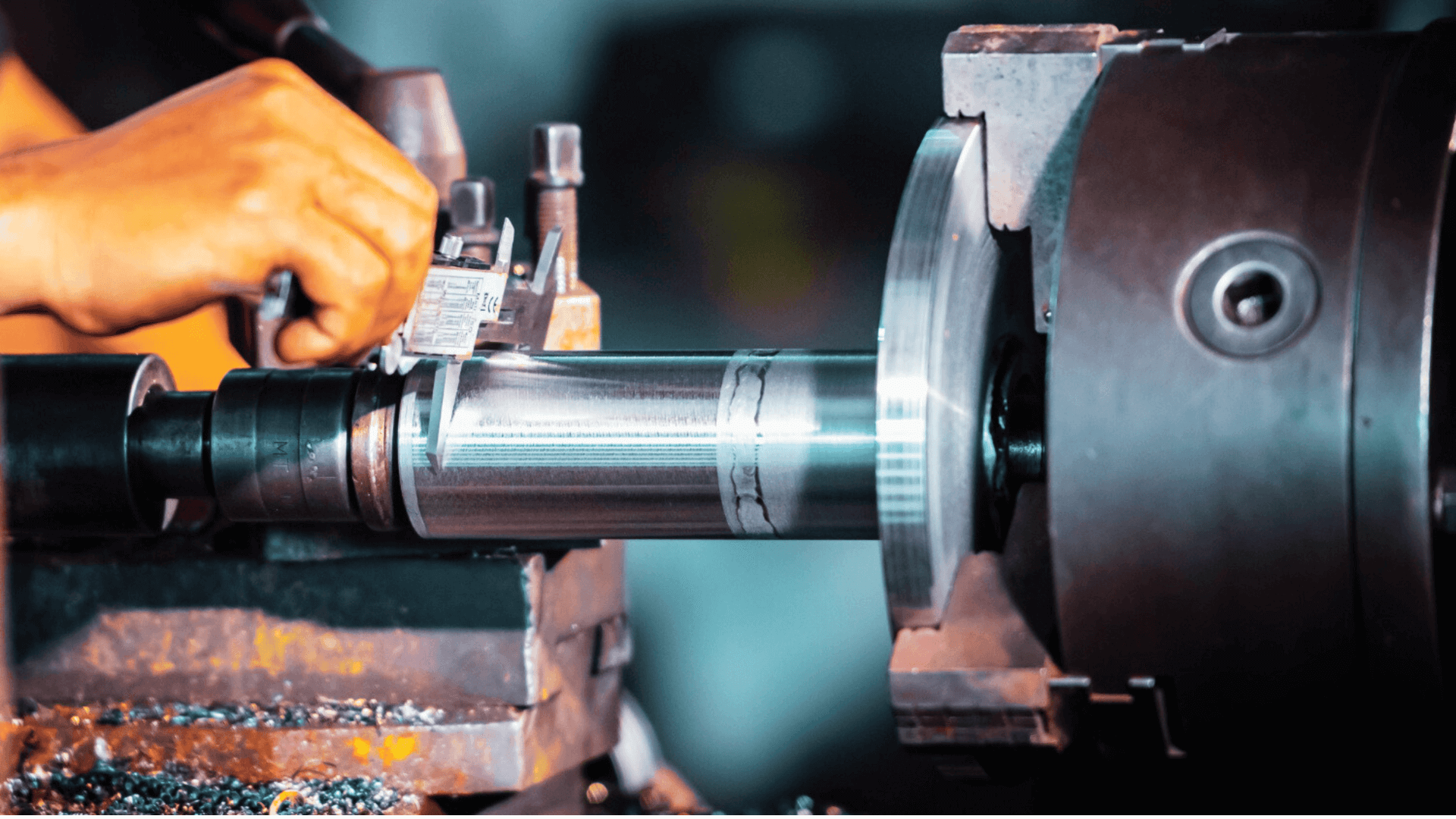

CNC machines use pre-programmed software to control tools and machinery – everything from lathes and mills to routers and grinders. Unlike traditional machines, these don’t need constant human intervention. Once the program is set, the machine executes complex tasks with accuracy that’s almost impossible to replicate manually.

What makes CNC truly powerful is the ability to create identical parts, again and again, without deviations. This is an essential advantage when manufacturing parts that demand tight tolerances, such as automotive components, aerospace fittings, or medical implants.

Common Types of CNC Machines Used in India

Indian industries, particularly in cities like Coimbatore, Ahmedabad, Ludhiana, and many others, rely on a variety of CNC machines. Some of the widely used types include:

- CNC milling machines: For shaping metals and plastics with rotating cutting tools

- CNC lathes: Best suited for producing cylindrical components

- CNC laser cutters: Used in sheet metal, signage, and decorative work.

- CNC plasma cutters: Ideal for heavy-duty metal fabrication

- CNC EDM (Electrical Discharge Machines): This high-quality CNC machining is used for intricate die and mould work.

Each type serves different needs, but they all share one goal – CNC machines work with precision and reliability. They also make manufacturing less labour-intensive.

What are the Advantages of CNC Machines over NC?

Why are CNC machines seen as a smarter investment with a wider range of applications than their older NC counterparts? Here’s a breakdown of the main advantages of CNC machines:

1. Superior Automation and Consistency

NC machines depend more heavily on operator control compared to CNC machines, making NC machines prone to inconsistency. CNC machines, on the other hand, run on precise digital codes that reduce variability and human error and increase accuracy and precision. Once a design is programmed, it can be repeated hundreds or thousands of times without a flaw, providing clear production advantages.

This is a game-changer for industries like automobiles or electronics, where even a 0.1 mm difference can lead to component failure.

2. Faster Turnaround and Higher Throughput

Time is money, especially when client timelines are tight. CNC machining allows work to go on continuously, even overnight, without supervision. This leads to faster production, reduced turnaround times, and higher volume capability.

Even better, if your shop runs multiple product lines, CNC allows for quick switching between tasks using saved program files, without losing time on manual recalibrations.

3. Simplifying Jobs

Creating intricate cuts or unusual designs manually is expensive and time-consuming. CNC machines can handle highly complex components using CAD-CAM software, allowing you to take on a wider variety of jobs with greater profit margins.

If you’re a job shop working for multiple industries, CNC opens up more business without extra manpower.

4. Better Material Utilisation

CNC machines are incredibly precise, meaning fewer errors and rework. Over time, this translates to significant savings in raw material costs, especially in industries dealing with machined parts and expensive alloys, metals, or composites in large quantities.

In contrast, errors on manual machines or even NC machines usually mean redoing the job from scratch.

5. Easier Training and Skill Building

Training an operator on NC machining processes takes years. But CNC machines come with user-friendly interfaces, simulations, and diagnostic tools tailored to the relevant manufacturing processes that reduce the learning time.

In fact, many Indian ITIs and polytechnics now train students specifically on CNC systems, making it easier to hire fresh talent for your shop floor.

6. Data-Driven Decision Making

Modern CNC systems come with precise control, performance tracking, fault diagnosis, and remote monitoring. This means your business can make parts while simultaneously monitoring parameters such as machine health, usage stats, and maintenance alerts.

These analytics make CNC machining a strategic advantage that helps improve uptime, reduce unscheduled breakdowns, and plan predictive servicing, which is impossible with basic NC machines.

Financing the CNC Upgrade

Now, let’s address the elephant in the room: the cost. Yes, CNC machines require a higher upfront investment than NC machines, but this is where machine loans and equipment financing come in.

Through Electronica Finance Ltd., you can:

- Access collateral-free machinery loans

- Avail custom EMI options suited to seasonal cash flow

- Get funding for both new and pre-owned CNC machines

- Apply with minimal documentation

- Track your loan status easily through the EFL Clik App.

This kind of financing support ensures MSMEs don’t need to delay tech upgrades due to working capital limitations. The gains in productivity, quality, and customer satisfaction pay off in the long run.

Final Thoughts

If you’re still using traditional NC machines, now is the time to reassess and choose the many advantages that CNC machines provide. The difference in speed, accuracy, and profitability that CNC offers can’t be overstated.

So, whether you’re scaling up production, planning exports, or just looking to streamline shop floor operations, the precision and efficiency of operating CNC machines is the future.

Explore flexible CNC equipment financing with Electronica Finance Ltd. today.

FAQs

What is the difference between CNC and normal machining?

CNC (Computer Numerical Control) machines operate through computer-generated codes and software programs, allowing manufacturers to automate and precisely control the movement of tools and machinery. This results in extremely accurate, consistent, and repeatable operation, even for complex or intricate components. CNC machines also run continuously with minimal human intervention, making them ideal for high-volume or precision-based industries.

Traditional or NC (Numerical Control) machining often relies on manual inputs or analogue systems. As a result, NC machining is generally slower, less flexible, and more prone to human error.

What are the benefits of CNC technology compared to traditional approaches?

CNC machines offer numerous advantages, such as better accuracy, faster production, automation, and lower error rates. It’s also easier to scale and adapt to complex or custom manufacturing needs with CNC machining’s advancements.

Are CNC machines cost-effective for small and medium-sized businesses?

Yes, CNC machines are cost-effective in the long run. While the upfront cost is higher, the long-term savings in labour, material, and time, combined with better quality machining operations, make CNC highly cost-effective.