The surge in demand for eco-friendly packaging has made paper bag manufacturing a fast-growing sector in India. Entrepreneurs, from small-scale operators to large commercial players, are exploring paper-bag-making as a sustainable business opportunity. And at the centre of it all lies the paper-bag-making machine, the core investment that determines your production efficiency, output quality, and overall profitability.

This guide is designed to give you a comprehensive overview of paper bag machines, their real-world performance, the often-overlooked technical aspects, and how to finance them smartly with a machine loan, whether you’re scaling an existing unit or starting from scratch.

Overview: What is a Paper Bag Making Machine?

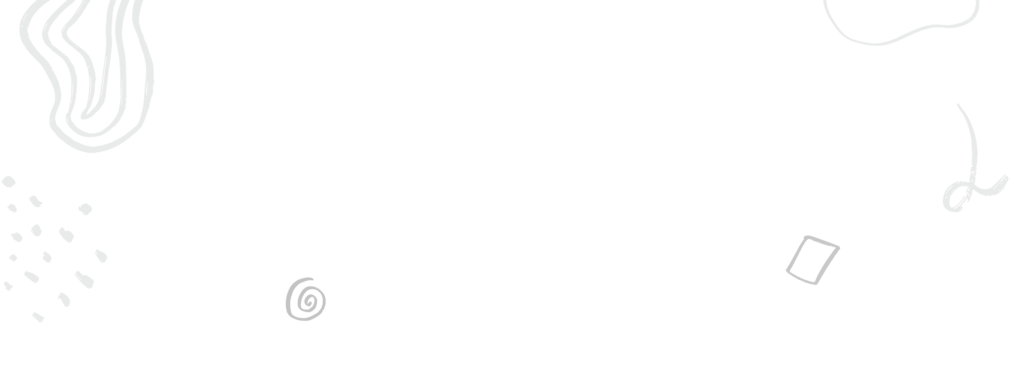

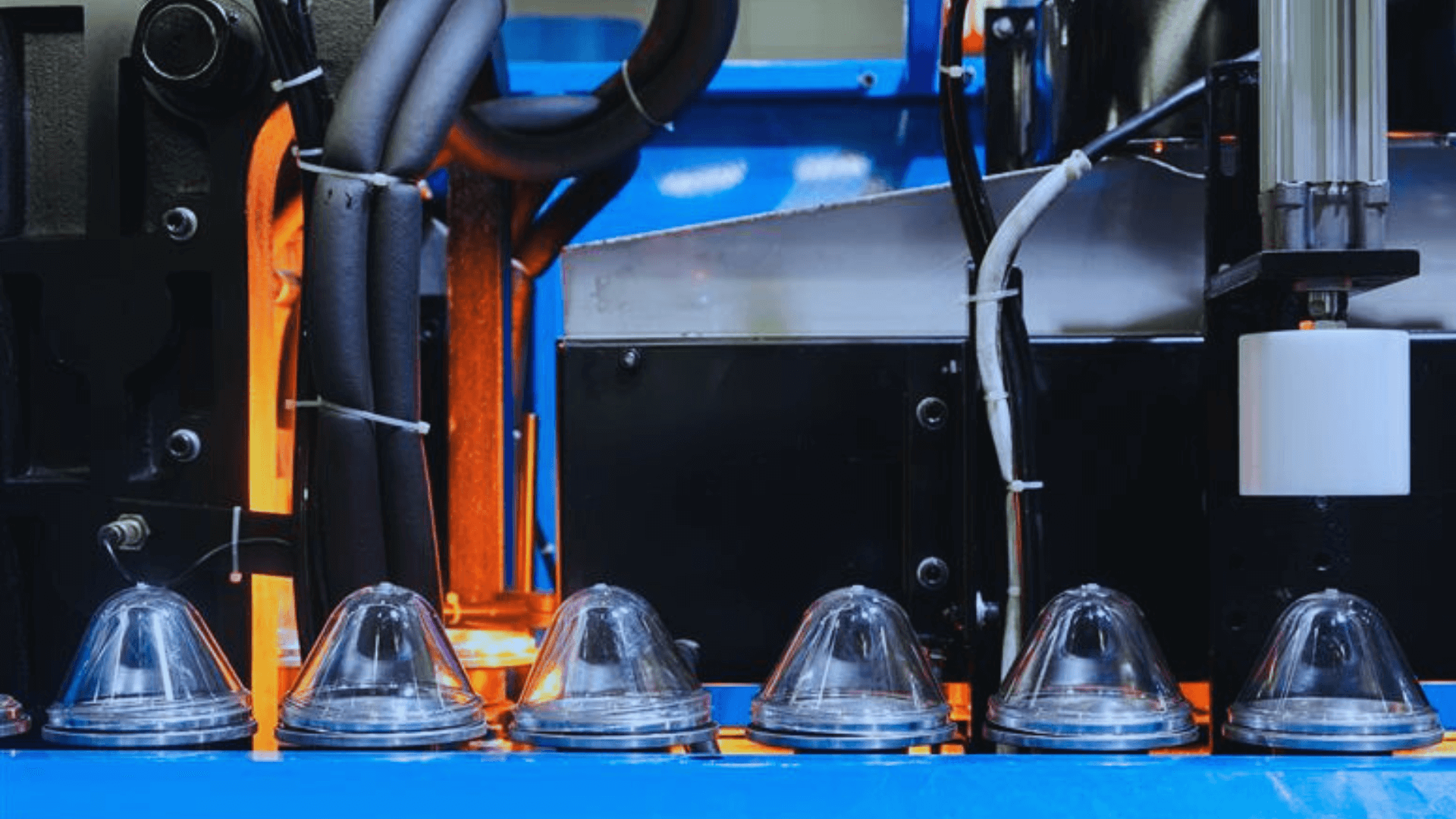

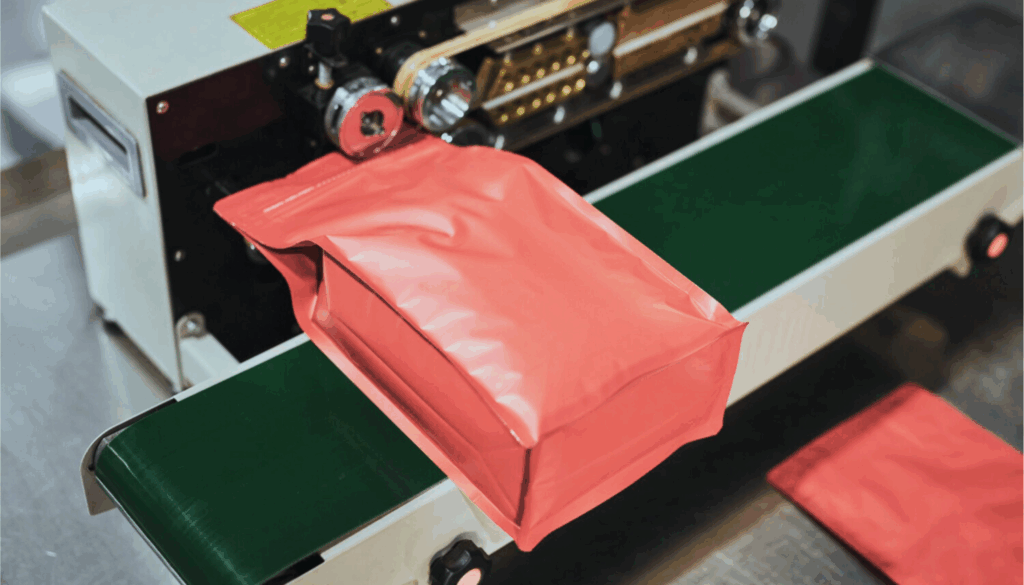

A paper bag making machine is a specialised equipment designed to produce paper bags at scale. Depending on the model, these machines can handle various sizes, shapes, and thicknesses of paper. This includes cutting, folding, pasting, and finishing paper into square-bottom, V-bottom, and other types of bags. These products cater to industries ranging from retail boutiques to bakeries and large grocery chains.

Modern paper bag-making machines offer:

- Versatility: Today’s machines are designed to handle a wide range of bag types and sizes, from lightweight satchel bags used in pharmacies to sturdy, reinforced carry bags ideal for groceries or fashion retail. Many models also allow quick changeovers between different bag dimensions, making them suitable for businesses catering to diverse customer needs.

- Speed and Efficiency: Advanced models can produce anywhere from a few hundred to over 20,000 bags per hour, depending on the configuration and paper quality. This high throughput is particularly valuable for businesses supplying to supermarkets, e-commerce packaging vendors, or large-scale retail chains where bulk orders are the norm.

- Automation: Modern systems integrate smart automation features that reduce manual intervention. This not only ensures precise folding, cutting, and pasting but also enhances consistency and reduces wastage, which is critical for keeping operational costs under control.

- Energy Optimisation: Many newer machines are engineered with energy-efficient motors and systems to help reduce power consumption without compromising on speed or quality, a crucial factor for businesses conscious of operational costs.

- Integration with Printing Units: Some models allow inline printing, enabling businesses to customise bags with logos or promotional designs during the production process, eliminating the need for separate branding runs.

- User-Friendly Interfaces: Touchscreen controls and digital dashboards make operation simpler, even for semi-skilled staff. Built-in diagnostics help operators identify and resolve minor issues quickly, reducing downtime.

For businesses in India, whether it’s a start-up bakery or an established packaging supplier, understanding these basics helps set realistic expectations.

Lesser-Known Technical Insights

While the specifications often highlight speed and size ranges, there are technical details that first-time buyers often miss:

- GSM (grams per square metre) Compatibility: Machines vary in the paper thickness they can handle, usually from 30 to 120 GSM. Choosing the wrong range can limit your product variety.

- Glue Application Systems: Advanced machines use precision gluing systems that minimise wastage and improve finish quality.

- Noise Levels: For setups in urban areas or compact workspaces, low-noise machines are a practical choice.

- Training and Support: Some manufacturers offer extensive onboarding support, while others expect operators to figure things out. This can significantly impact productivity in the first few months.

- Spare Parts Availability: Machines from lesser-known brands may save costs initially, but can create downtime issues if spare parts are hard to source locally.

- Changeover Flexibility: Some machines allow quick size or design changeovers with minimal downtime, which is invaluable if you cater to multiple clients or frequent custom orders.

- Integrated Quality Checks: Premium models may include sensors or cameras that detect misfeeds, alignment errors, or improper glueing, reducing wastage and ensuring consistent product quality.

- Scalability Options: Machines designed with modular upgrades let you expand capacity or add features (like printing or handle attachment) without replacing the core system.

- Warranty and Service Contracts: Comprehensive warranties and AMC (Annual Maintenance Contract) options can save significant costs and stress over the machine’s lifespan.

These lesser-known aspects can affect long-term efficiency and cost-effectiveness, so they’re worth factoring into your buying decision.

Production Capacity vs Real-World Output

Brochures may boast of producing 15,000 bags per hour, but real-world output often tells a different story. The following factors can reduce actual production to 70-80% of the advertised speed:

- Operator skill level

- Paper quality and supply consistency

- Downtime due to changeovers or maintenance

Understanding your real production needs helps you choose a machine that balances cost and performance and ensures efficient demand planning.

Power Consumption and Utility Requirements

Power usage is a significant operational cost. A semi-automatic machine may need 3–5 kW, while a fully automated high-speed machine could require 12–15 kW. Also, maintaining a stable power supply and adequate compressed air (for pneumatic systems) is essential for smooth operations. A common oversight is underestimating power and utility needs. Here’s what to check:

- Electrical Load: Machines may require single-phase or three-phase connections, depending on their size.

- Backup Requirements: Consider inverters or generators to prevent downtime.

- Air Compressors: Some advanced models need compressed air for specific operations.

These factors don’t just affect your initial setup cost but also ongoing expenses. Planning for these up front can prevent unexpected financial strain.

Machine Maintenance and Common Oversights

Even the most advanced paper bag-making machine isn’t “fit and forget.” Routine care keeps operations smooth and avoids costly breakdowns. Many businesses delay scheduled servicing, which eventually reduces efficiency and output quality. Ignoring small issues, such as unusual noise or slightly skewed printing, often leads to bigger, more expensive problems later.

Here’s what smart operators do:

- Daily Cleaning: Dust and paper scraps can jam sensors or belts

- Lubrication Schedules: Regular lubrication prolongs motor and gear life

- Parts Inventory: Keeping essential spares like belts and rollers reduces downtime during breakdowns

Automation Doesn’t Mean Zero Monitoring

Fully automated machines may sound like a dream, but human oversight remains crucial as it ensures consistent quality and reduces wastage during batch changes or special orders. Think of automation as reducing manual work, not eliminating operational involvement entirely. Operators need to:

- Inspect glue levels and paper rolls

- Monitor output for quality consistency

- Adjust settings during production runs

Cost Factors Beyond the Machine Price

The machine’s sticker price is just one component of your investment. Businesses often overlook these additional costs:

- Installation and Setup: Electrical, structural, and training expenses

- Raw Materials: Quality paper, glue, and inks

- Ongoing Maintenance: Annual service contracts or periodic replacements

- Downtime Costs: Lost revenue during repairs or changeovers

These often-overlooked costs can impact your financial planning significantly.

How to Choose the Right Machine Loan

Financing a paper bag-making machine loan can make or break your investment. NBFCs like Electronica Finance Limited (EFL) specialise in customised loans for businesses like yours. Here’s what to consider:

- Flexible Repayment Options: Look for EMI structures that match your business cash flow

- Quick Disbursement: Fast loan processing means you don’t lose out on deals due to delays

- Competitive Interest Rates: The lower the rate, the faster your return on investment

- No Heavy Collateral: Ideal for small and mid-sized businesses wanting to scale without risking major assets

Use the EFL Clik App to calculate your eligibility, estimate EMIs, and even apply seamlessly.

Conclusion

Paper bag manufacturing is a promising venture, but the right machine and financing strategy make all the difference. Take time to understand technical details, plan for realistic output, and manage costs beyond the upfront machine price. And when ready, consider exploring financing options such as machine loans through EFL to get a head start on your investment without straining cash reserves.

FAQs

What is the actual production speed of a paper bag machine?

While machines may be rated for 10,000+ bags per hour, actual output is usually 70%–80% of the advertised speed, depending on operations and material quality.

How often should a paper bag machine be serviced?

Basic maintenance should be done daily, with full servicing every 6–12 months, depending on usage intensity.

What’s the electricity cost of running a paper bag machine daily?

It varies by size and capacity, but for a medium unit running eight hours, expect electricity costs of around ₹800–₹1,200 per day.

Which type of paper is best for long-lasting bags?

Paper with a higher GSM (grams per square metre) offers better durability and is ideal for heavy-duty or reusable paper shopping bags.