CNC machines, short for Computer Numerical Control machines, are versatile tools used in various industries for precision manufacturing and automation. These machines utilise computer programming to control their movements and operations, resulting in highly accurate and efficient production processes.

Acquiring a CNC machine for your business can be a significant investment, and it’s not uncommon for businesses to seek financing options to facilitate the purchase. CNC machine financing provides an opportunity to spread the cost of acquisition over time, allowing businesses to access the latest technology and improve their capabilities without significant upfront capital outlay.

Whether you’re a small business owner looking to upgrade your equipment or an entrepreneur starting a new venture, understanding the financing options available is crucial to making an informed decision.

This is a definitive guide on CNC machine financing. By the end of this guide, you’ll have a comprehensive understanding of the financing landscape for CNC machines, empowering you to make informed decisions that align with your business needs, financial situation, and long-term goals. Let’s dive into CNC machine financing and explore the options available.

What is a CNC?

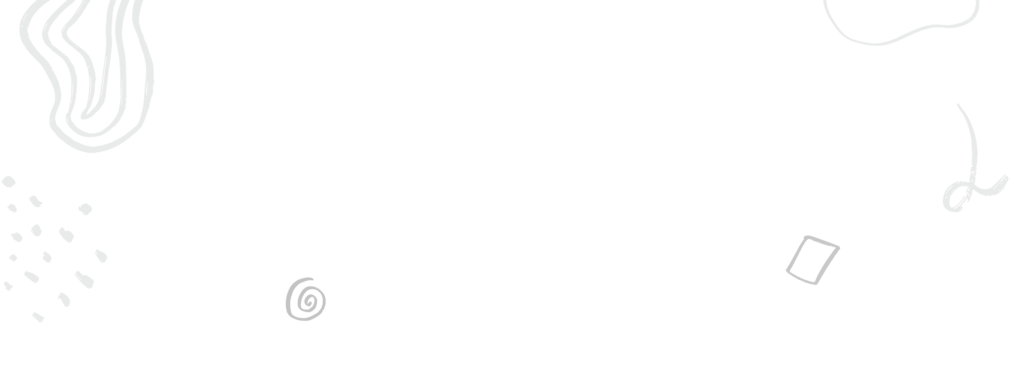

CNC stands for Computer Numerical Control. It refers to the automation of machine tools through computer programming. CNC machines use coded instructions to control their movements and operations with high precision and accuracy. These instructions guide the machine to perform various tasks such as cutting, milling, drilling, and shaping materials.

What is a CNC used/purpose for?

CNC machines have many applications for manufacturing and fabrication processes that require precise and repetitive operations. Industries such as automotive, aerospace, electronics, woodworking, etc., use CNC machines. Their purposes include producing complex parts, creating prototypes, engraving designs, and enhancing overall production efficiency.

What Are the Types of CNCs?

CNC machines come in various types, each tailored to specific applications and machining tasks. Here are some common types of CNC machines:

- CNC Mills: These machines use rotating cutting tools to remove material from the workpiece. They are versatile and can perform drilling, cutting, and contouring operations.

- CNC Lathes: Lathes rotate the workpiece while a cutting tool shapes it. They are used for cylindrical or spherical parts and can perform tasks like turning, facing, and threading.

- CNC Routers: Woodworking and sign-making industries commonly use routers for cutting, shaping, and engraving materials like wood, plastic, and foam.

- CNC Plasma Cutters: These machines employ a high-velocity jet of ionized gas to efficiently cut through metal with precision. They prove exceptionally well-suited for precise metal cutting tasks, especially in industries like automotive and HVAC fabrication.

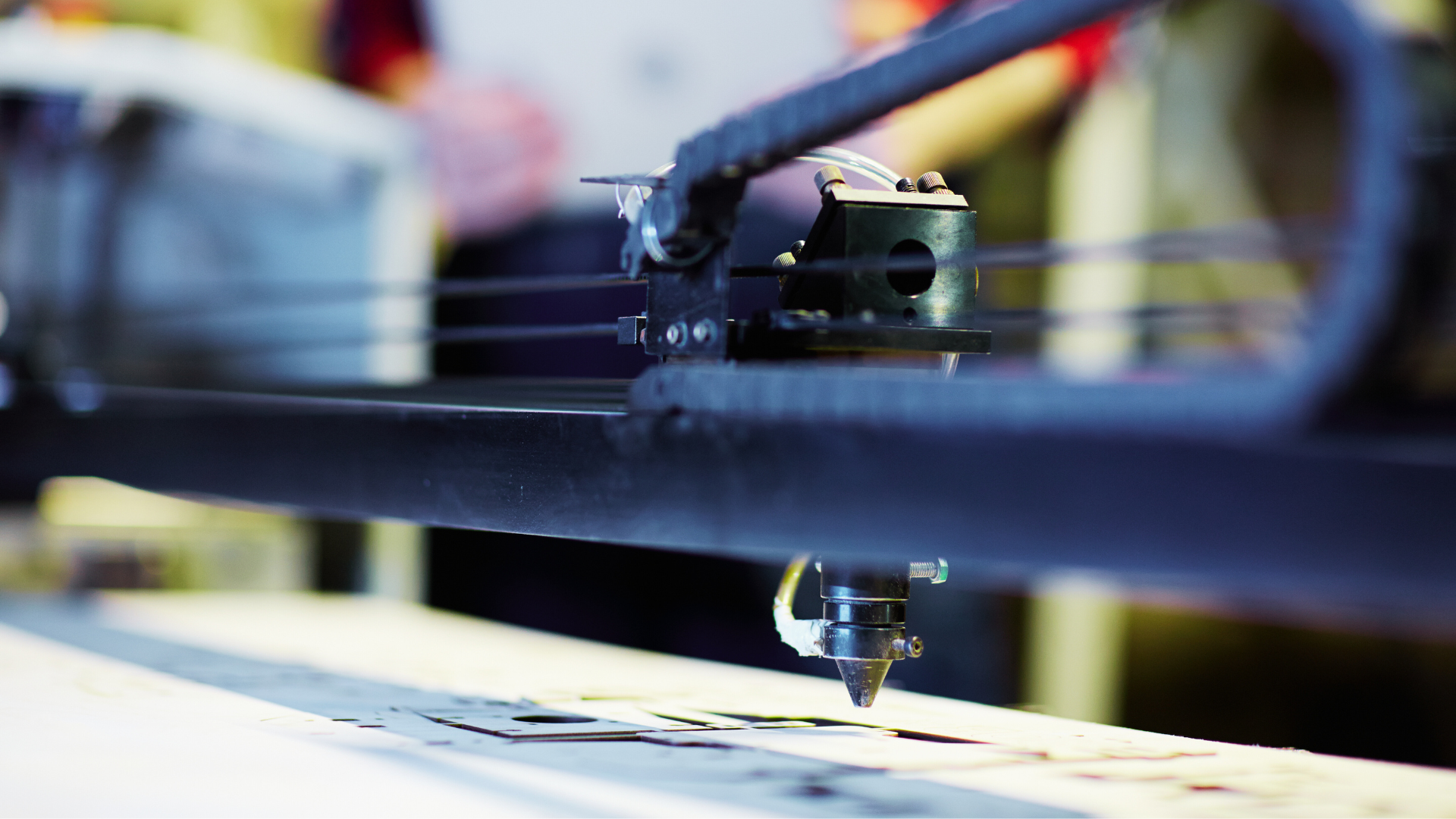

- CNC Laser Cutters: Laser cutters use laser beams to precisely cut or engrave metal, wood, and acrylic materials. They offer high precision for industries like jewellery making and signage.

What are the benefits of CNC?

The utilisation of CNC machines offers several notable benefits:

- Precision and Accuracy: CNC machines can consistently produce highly precise and accurate parts, improving product quality and reducing wastage.

- Increased Productivity: Automation and computer-controlled operations enable CNC machines to perform tasks faster and more efficiently than manual methods, enhancing overall productivity.

- Versatility: CNC machines can handle various materials and perform diverse operations, allowing for flexibility in manufacturing processes.

- Complexity and Repetition: CNC machines produce complex shapes and execute repetitive tasks consistently, reducing human error and increasing efficiency.

- Cost-Effectiveness: CNC machines can reduce labour costs by automating processes, minimising the need for manual intervention, and optimising material usage.

What are the features/functions of CNC?

CNC machines offer various features and functions that contribute to their versatility and efficiency:

- Programmable Control: CNC machines are operated through computer programming, allowing precise control of movements and operations.

- Multi-Axis Capability: CNC machines can move in multiple axes simultaneously, enabling complex and multidimensional machining.

- Tool Changers: Automatic tool changers allow CNC machines to switch between different tools without manual intervention, reducing setup time.

- Coolant Systems: Coolant systems help maintain appropriate temperatures during machining, extend tool life, and improve surface finishes.

- Automatic Workpiece Positioning: CNC machines can automatically position the workpiece, enabling efficient machining and reducing setup time.

- Integrated CAD/CAM Compatibility: CNC machines can interface with computer-aided design (CAD) and computer-aided manufacturing (CAM) software, simplifying the programming and machining process.

How to choose the right CNC for you?

Choosing the right CNC machine for your specific requirements involves several considerations:

- Material Compatibility: Determine the materials you will be working with to ensure the chosen CNC machine can handle them effectively.

- Workpiece Size and Complexity: Assess the size and complexity of the parts you need to produce to ensure the CNC machine’s working area and capabilities align with your needs.

- Precision Requirements: Consider the precision required for your applications and choose a CNC machine to deliver the desired accuracy.

- Available Space: Evaluate the available space in your workshop or production facility to ensure proper installation of the CNC machine.

- Budget: Set a budget for your CNC machine investment and explore options that offer the best value for your financial resources.

- Future Expansion: Consider your future production needs and assess whether the chosen CNC machine has upgrade options.

What is the process to avail of CNC machine loans?

Machine loans offer an appealing option for Micro, Small, and Medium Enterprises (MSMEs) seeking quick and convenient funding. This is particularly beneficial when immediate cash is required to ensure smooth and efficient business operations.

Here are the benefits of EFL machinery loan:

- Maximum Loan Amount: Up to Rs. 3 Crores.

- Loan Repayment Period: 5 years.

- Attractive Interest Rate: Enjoy flexible interest rates.

- Faster Disbursal: Loan disbursement within three working days.

- No Collateral Required: No need for additional collateral.

Our CNC machine financing benefits businesses with high-growth potential that need capital for equipment purchases or business expansion. It also allows companies to diversify their assets by investing in physical equipment rather than solely relying on cash.

Here are several reasons why you should choose our machine loan:

- Maintains a Consistent and Strong Cash Flow: With our machine financing option, you can spread the cost of the machine over time, utilizing the profits generated by your business. This approach safeguards your cash flow and promotes financial stability for your operations.

- Reduces Stress on Working Capital: By obtaining a loan specifically for machinery purchase, you can reduce the strain on your working capital. This relieves financial burdens and allows for smoother business operations.

- Trusted by Thousands of Businesses: With over 30 years of experience, Electronica Finance Limited is an RBI-registered non-banking financial company (NBFC). We have a track record of successfully assisting over 25,000 businesses and financing over 50,000 machines.

- Purchase Expansion: If your business is experiencing growth and requires additional capital beyond your current bank’s offerings, our loan against machinery can provide the extra funds needed for expansion projects.

- Personalised Support: Our dedicated team of experts will guide you throughout the machine loan application process. We will work closely with you to ensure you secure the best possible rate and payment plan tailored to your business needs and budget.

What are the eligibility criteria and documentation process to procure a CNC machine loan?

Machinery and equipment form the foundation of any industry, manufacturing, or service. Investing in good machinery and equipment is essential for smooth and efficient operations. However, purchasing machinery can be costly. That’s where our machine loan comes in.

Whether you’re looking to acquire new machinery or expand your existing equipment, we provide loans for various types of machinery and equipment.

From manufacturing plants to food processing equipment, our machine loan caters to a wide range of needs. The application process for our machine loan is easy and transparent. Click “Apply Now,” visit our website, and fill in the necessary details. Our tele-calling team will contact you within 24-48 hours to further discuss the process and provide additional information.

Eligibility for a machinery loan requires meeting certain criteria, which may vary depending on the issuing bank or institution. Generally, a Bureau Score of more than 700 and at least one owned premises is among the common eligibility requirements.

To complete the loan application, you will need to provide the following documents:

- 3 Years Balance sheet and ITR

- 12 Months Bank Statements of all Banks

- GST Returns for the current year

- KYC – Aadhar & PAN

- Residence & Factory ownership proof

- Proforma Invoice / Quotation

- 12 months’ electricity bills

Key Takeaways

Electronica Finance offers CNC machine loans that provide a tailored solution for businesses seeking financial support for their equipment acquisition.

Electronica Finance offers customised solutions with reasonable interest rates, flexible money utilisation, and increased loan amounts. Our simple borrowing method will help you achieve your business objectives.

We understand the unique challenges you face, and we strive to be your trusted financial partner. With Electronica Finance, you can experience the difference as we offer machine loan solutions that pave the way for your financial success.

Contact Electronica Finance to explore the possibilities and discover how our CNC machine loans can support your business growth. By following our streamlined process and providing the necessary documentation, you can easily apply for a machinery loan and take advantage of our machine financing services.